|

|

|

|

|

|

|

|

A.C. Pressure Pipes :- |

|

|

Hari AC Pressure Pipes are made from

a careful blend of imported Asbestos Fiber generally imported from

Canada & Russia, and high quality cement. Hari Pressure Pipes are

manufactured on highly sophisticated and modern machines by skilled

personnel. |

|

Stringent quality control procedures

at various stages ensure a consistently high standard product which

even exceeds Is specifications. |

|

Fibre Reinforcement :- The manufacture

of Asbestos Cement Pressure Pipes exploits to the full, the strength

, flexibility and indestructibility of the Asbestos Fibres. These

fibers provide the reinforcement for the cement, the two materials

make the perfect bond. The raw material is carefully processed and

mixed by wet process which ensures uniform high quality of pipes.

|

|

Easy to join easy to remove :- Hari

Industries

offers both CID joints and AC coupling for easy installation. Both

these types of joints offer flexibility and ensure watertightness. |

|

Certificate of Performance :- Hari

Pressure Pipes are stamped with ISI mark as per IS : 1592 promising

reliable performance and genuine long term economy. Our list of

clients include various Govt. Departments all over the country,

public and private undertakings. |

|

USES :- AC Pressure Pipes enjoy

multiple uses including the following

-

Agriculture

-

Irrigation

-

Lift Irrigation

-

Municipalities

-

Projects and colonies works with

contractors.

-

Public Health Departments of various

States.

-

Water Supply and sewage schemes.

-

Under drainage of lined canals

|

|

How to Store :- |

|

Pipe must be stacked

properly as shown, to avoid damage. The width and depth of the

trench works should be as recommended in the diagram. The excavated

soil should be dumped on the traffic side of the trench to form a

protection. Space of about 0.5 meter should be left along the trench

for workmen to move freely. |

|

|

Product Facts :- Hari AC

Pressure pipes have a standard length of 4m. They are available in

nominal Diameters of 80, 100, 125, 150, 200, 250 & 300 mm in Classes

10, 15 & 20. |

| |

|

Coupling and Joints :- |

|

|

Hari AC Pressure Pipes can easily be

joined together with AC Hydrotite Coupling or Cast Iron Detachable

Joints. |

| |

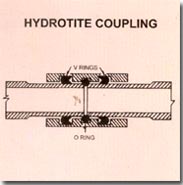

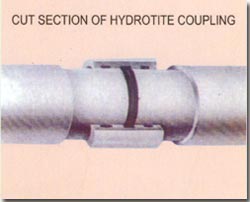

| Hari AC

Hydrotite Coupling :- |

|

Hari Hydrotite Joint Consists of a

precision machined AC Hydrotite Coupling with three innner grooves

fitted with one rubber 'O' ring in the centre and two scientifically

designed rubber 'V' rings on either side. The 'O' ting ensures

separation of the two pipes in the coupling and allows flexibility.

The 'V' rings combine the principle of compression and hydrostatic

sealing to ensure watertightness. |

|

| |

|

Laying and jointing of Pipes :- |

|

|

-

Clean the pipe ends the components

of CID joints. The CID joint comprises a central collar, two

flanges , two round rubber rings, bolts and nuts. The two rubber

rings placed on the pipe ends and copressed between collar and

flange , by means of steel bolts provide the necessary sealing.

Since rubber rings for pipes of diameters 150 mm and below cannot

be placed on the pipes by stretching, an AC or wooden cone

may be used for this purpose.When placed by the above method, the

rubber ring will not be in the correct position. Hence it is

essential to make a site gauge as illustrated n the figure and the

ring is brought to the correct position.

|

-

Insert the flanges on pipe ends.

With the help of wooden cone place the rubber rings on pipe

ends and roll them to the correct position.

-

Place the central collar of the laid

pipe close to the pipe to be joined . Centralise the collar,

leaving a gap of about 5mm between the pipe ends.

-

Now position the rings to touch the

collar end. Move the flanges close. Insert bolts in the flange

holes and tighten them. The bolts should be tightened uniformly to

ensure a leak proof joint.

-

After testing the pipeline , the

trench should be filled up.

|

|

Note :- We can also provide ISI marked

C.I. Detachable Joints, C.I. P/E Specials, C.I.D/F Fittings & Pipes. |

| |

|

S.L. No. |

NOM Dia.

(mm) |

Class - 10 |

Class - 15 |

Thickness

(mm) |

External Dia

(mm) |

Thickness

(mm) |

External Dia

(mm) |

|

i |

80 |

9.5 |

99.5 |

9.5 |

99.5 |

|

ii |

100 |

9.5 |

120.0 |

10.0 |

121.0 |

|

iii |

125 |

9.5 |

145.0 |

11.0 |

147.0 |

|

iv |

150 |

9.5 |

171.0 |

13.0 |

176.5 |

|

v |

200 |

11.5 |

225.0 |

16.5 |

233.5 |

|

vi |

250 |

12.0 |

276.5 |

17.0 |

284.5 |

|

vii |

300 |

14.0 |

328.5 |

20.0 |

340.5 |

|

|

Tests and specifications :- |

|

Hari A.C. Pressure pipe are

manufactured and tested for strict conformity to Is 1592/89 G.G.

Pipes Pvt. Ltd., Kaladera, Jaipur have got a sophisticated

laboratory with the most modern equipment for testing A.C. Pressure

pipes. |

| 1.

Hydradraulic Pressure Tightness Test :- |

| Every

pipe is tested to he pressure corresponding to the class of pipe as

given below : |

| |

|

Class of Pipe |

Test Pressure in Kg./cm2 |

Max. recommended

Working Pressure Kg./cm2 |

|

10 |

10 |

5.0 |

|

15 |

15 |

7.5 |

|

20 |

20 |

10 |

|

| |

| The pipe

is placed in a hydraulic press and the hydraulic pressure inside the

pipe is progressively increased to the specified value and

maintained for a minimum of 30 seconds. Pipes should not indicate

any sweating on the outside. |

| |

| 2.

Hydraulic Bursting Test :- Hari Pressure pipe are tested to satisfy

a minimum unit bursting stress of 20 N/mm2 for sizes upto and

including 300 mm diameter. |

| |

| 3.

Transverse Curshing Stress :- The unit Transverse crushing stress

arrived at from transverse crushing test shall not be less than 44

N/mm2. |

| |

|

4. Longiudinal Bending Test :- The

unit longitudinal bending stress arrived at from longitudinal

bending test shall not be less than 24.5N/mm2. Only pipes of

150mm dia and less are tested for longitudinal bending strength

increases considerably as the section modules increases and

therefore need not be separately considered. |

| |

|

5. Hari A.C. Pressure Pipes also

satisfy the following ratios between Bursting Pressures (BP),

Hydraulic Test Pressures (TP) and Normal Hydraulic Working Pressures

(WP) |

| |

|

Nominal Dia. |

BP/TP |

BP/WP |

|

80 and 100 |

2.00 |

4.0 |

|

125 to 200 |

1.75 |

3.5 |

|

250 to 300 |

1.50 |

3.0 |

|

| |

| |

|

|

| |

| |

| |

| |